diff --git a/Readme.md b/Readme.md

index c03d41f..05625b7 100644

--- a/Readme.md

+++ b/Readme.md

@@ -7,33 +7,49 @@

## 1 - Design

-_Coming soon !_

+We call this one-way valve "_respiratory_" because it was designed to be adaptale to the low cracking-pressure requiered by breahting-related application. This is because this one-way valve was designed to integrate with our open-source 3D-printed gaz mask : [distorsion/3D-printed-parametric-gaz-mask](https://git.deuxfleurs.fr/distorsion/3D-printed-parametric-gaz-mask)

+

+In this repo we provide all the element of the valve (_as described bellow_), and the body of the valve (_either_ [3Dfiles/owv_input_body.stl](./3Dfiles/) _or_ [3Dfiles/owv_output_body.stl](./3Dfiles/) _depending on if you want a filter at the output/input or not_) that can be integrated into your project.

## 1.a - Membrane design

+In the first design of one-way valve for ou gaz mask, we first used a very soft membrane made of thin silicone. In this design, the membrane is actually 3D printable, either out of "_normal_" material (_preferably PETG_) or out of flexible filament.

+

+While this requieres a larger diameter to obtain the low cracking pressure, this allows the valve to automatically close without negatiev pressure, which is needed for breathing-related application as we aren't constantly breathing in an out, and there can be a second of hang durng which a softer membrane wouldn't close and would let air go the wrong way.

+

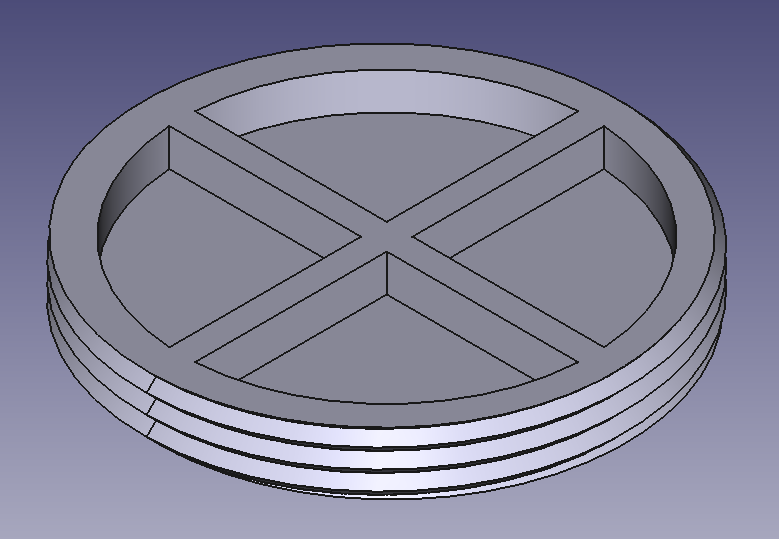

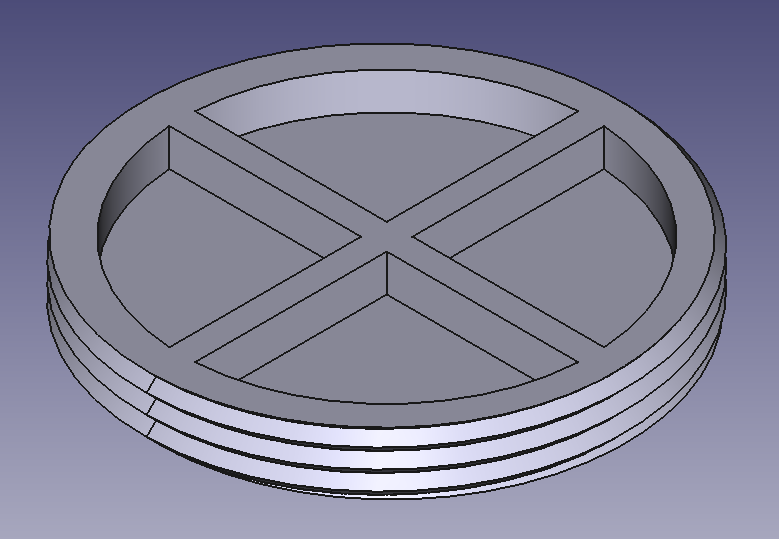

+The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

+

+The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

+

-_Coming soon !_

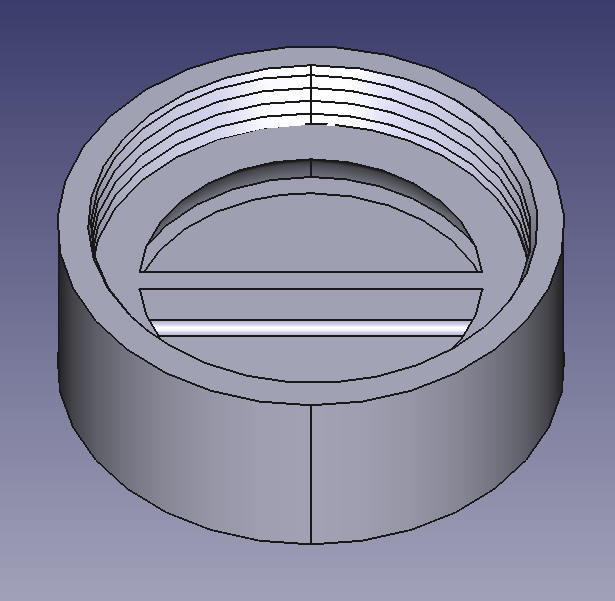

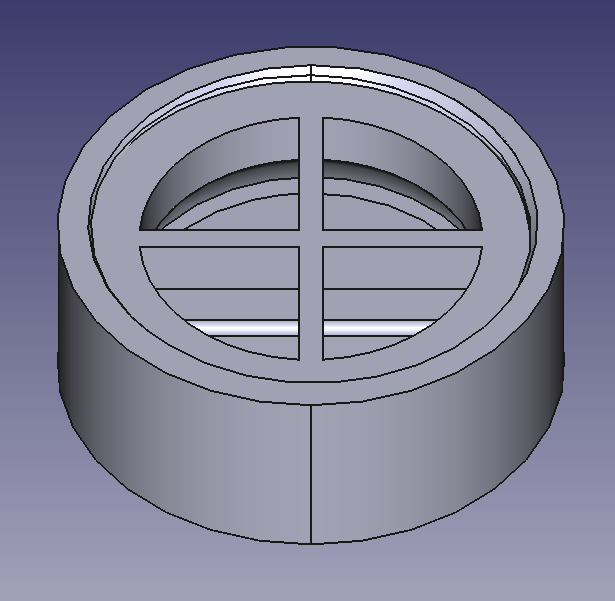

+Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

+

+There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

-_Coming soon !_

+Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

+

+There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

-_Coming soon !_

+We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

+Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

+

-_Coming soon !_

+We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

+Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

+

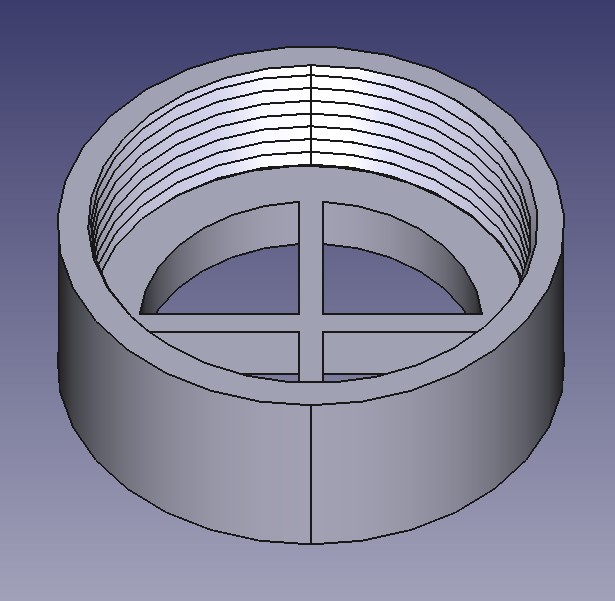

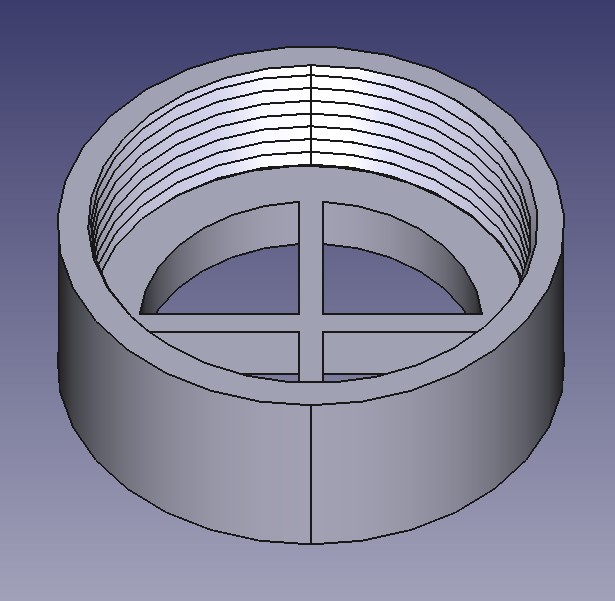

+We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

+

+We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

+

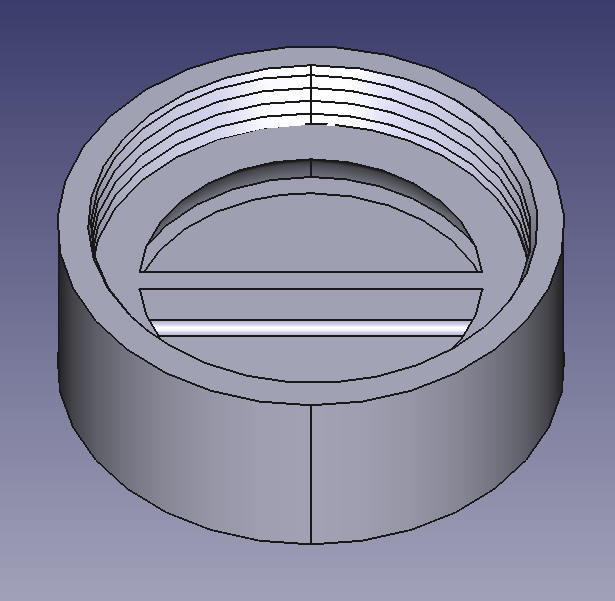

+We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

+

+We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

+

-_Coming soon !_

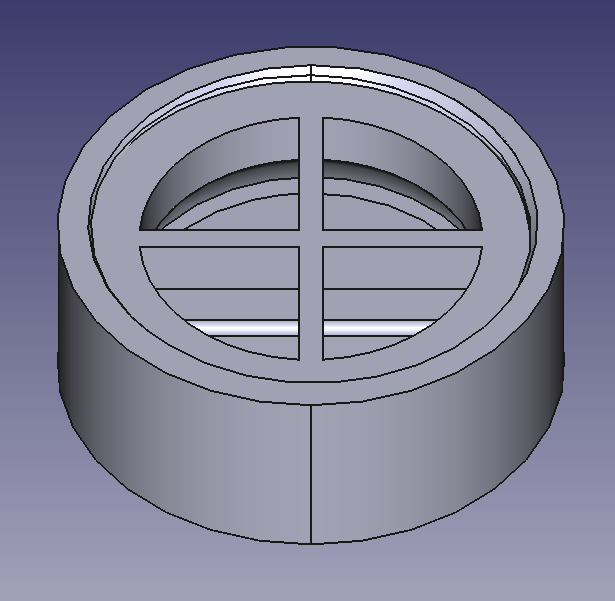

+Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing

-_Coming soon !_

+Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing

+The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

+

+The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

+

-_Coming soon !_

+Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

+

+There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

-_Coming soon !_

+Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

+

+There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

-_Coming soon !_

+We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

+Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

+

-_Coming soon !_

+We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

+Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

+

+We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

+

+We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

+

+We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

+

+We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

+

-_Coming soon !_

+Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing

-_Coming soon !_

+Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing