# 3D Printed parametric respiratory one-way-valve

## _Valve paramétrique adaptable à la réspiration imprimé en 3D (**version francaise [ici](./Readme.fr.md)**)_

[](./Readme.fr.md)

[](./Readme.md)

## 1 - Design

We call this one-way valve "_respiratory_" because it was designed to be adaptale to the low cracking-pressure requiered by breahting-related application. This is because this one-way valve was designed to integrate with our open-source 3D-printed gaz mask : [distorsion/3D-printed-parametric-gaz-mask](https://git.deuxfleurs.fr/distorsion/3D-printed-parametric-gaz-mask)

In this repo we provide all the element of the valve (_as described bellow_), and the body of the valve (_either_ [3Dfiles/owv_input_body.stl](./3Dfiles/) _or_ [3Dfiles/owv_output_body.stl](./3Dfiles/) _depending on if you want a filter at the output/input or not_) that can be integrated into your project.

## 1.a - Membrane design

In the first design of one-way valve for ou gaz mask, we first used a very soft membrane made of thin silicone. In this design, the membrane is actually 3D printable, either out of "_normal_" material (_preferably PETG_) or out of flexible filament.

While this requieres a larger diameter to obtain the low cracking pressure, this allows the valve to automatically close without negatiev pressure, which is needed for breathing-related application as we aren't constantly breathing in an out, and there can be a second of hang durng which a softer membrane wouldn't close and would let air go the wrong way.

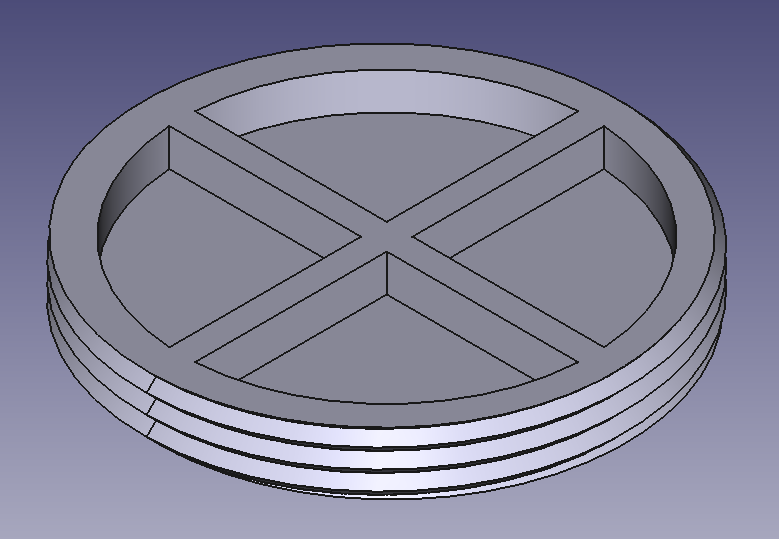

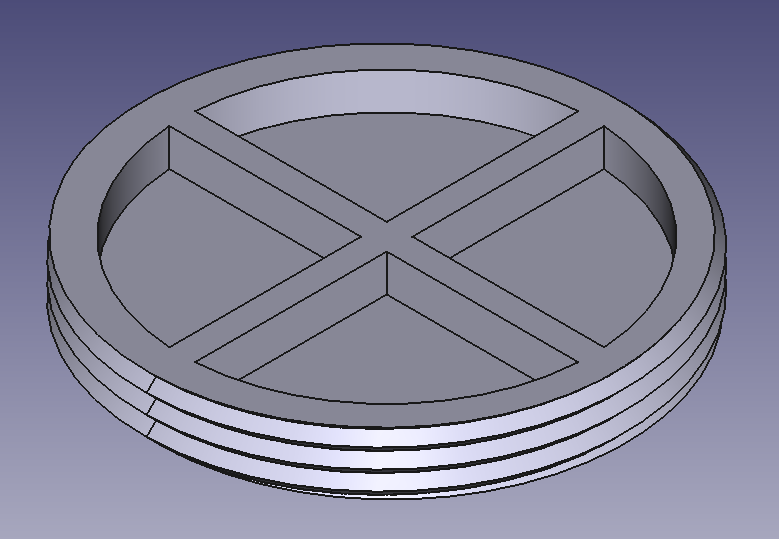

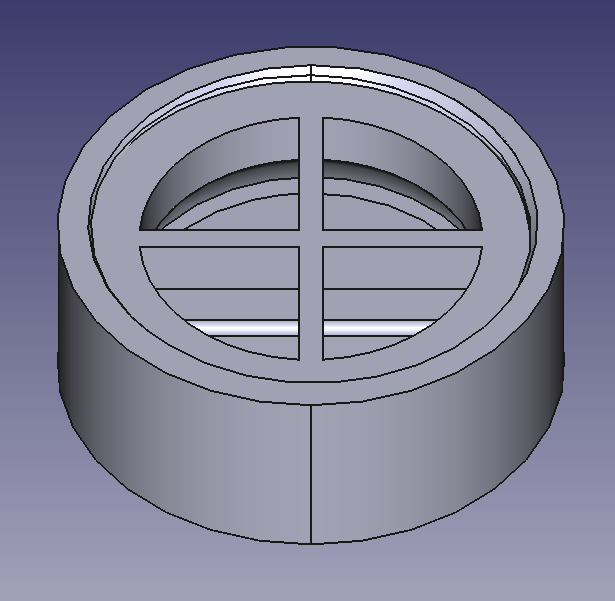

The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

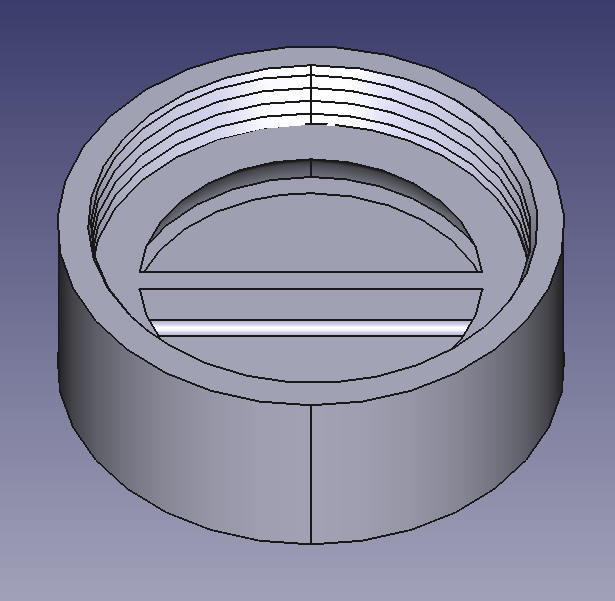

Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

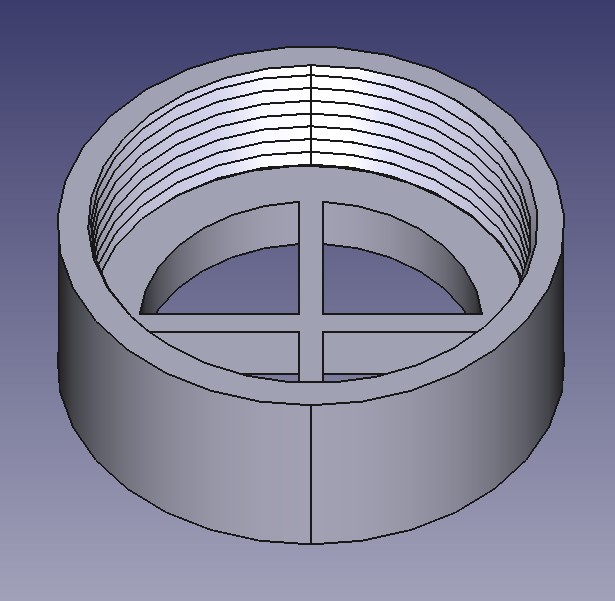

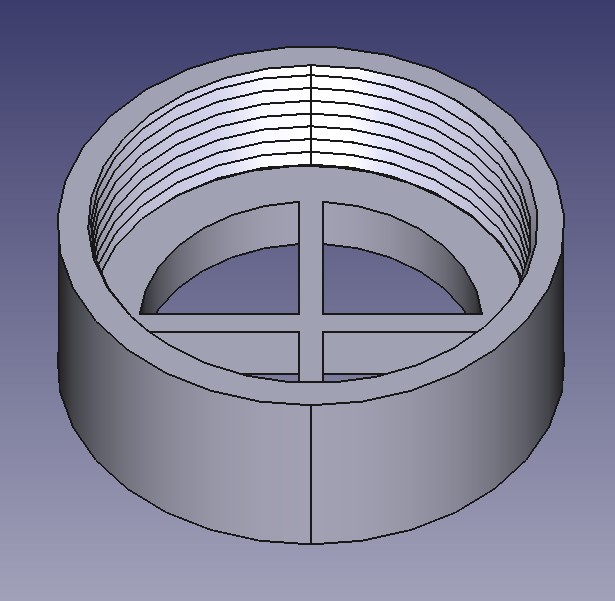

We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

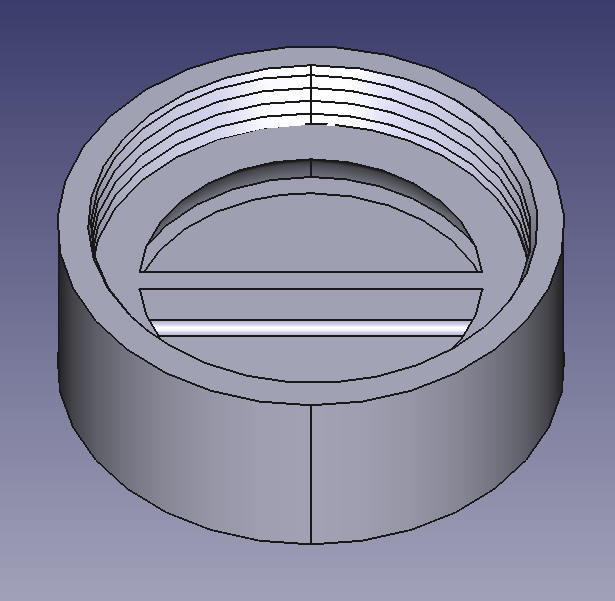

We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

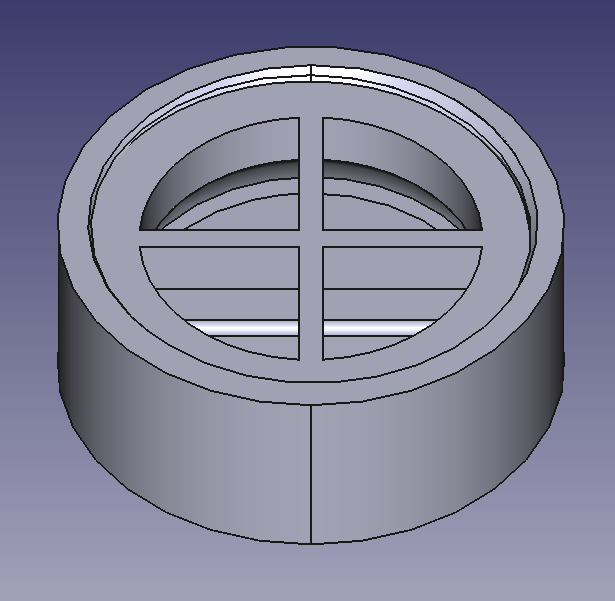

Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing

Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing

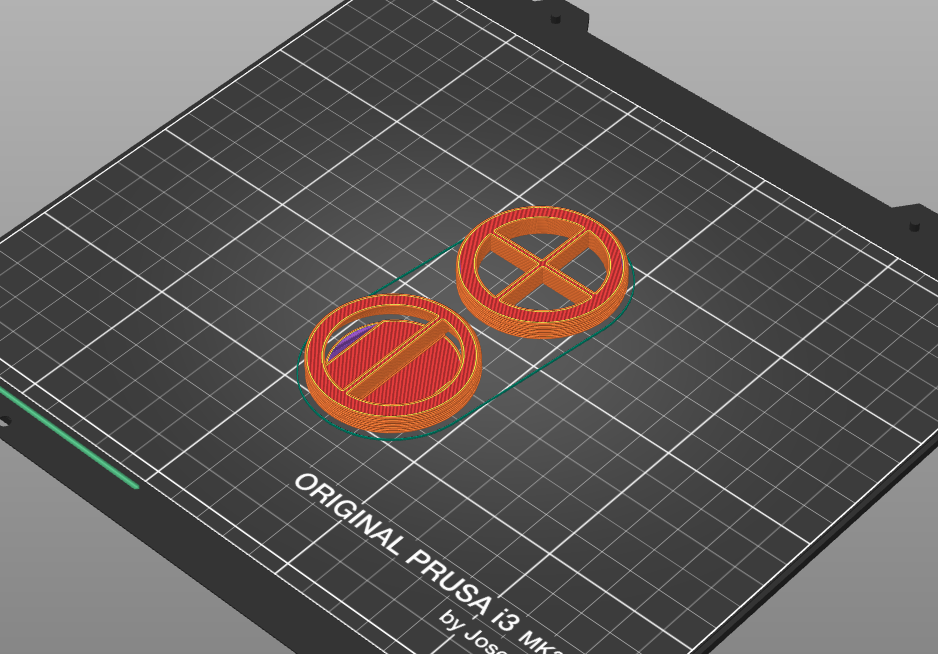

There is not much to be know abount printing this one-way valve : You can use prety much any material, although PETG is prefered for he membrane as it is flexible and won't fatigue over time.

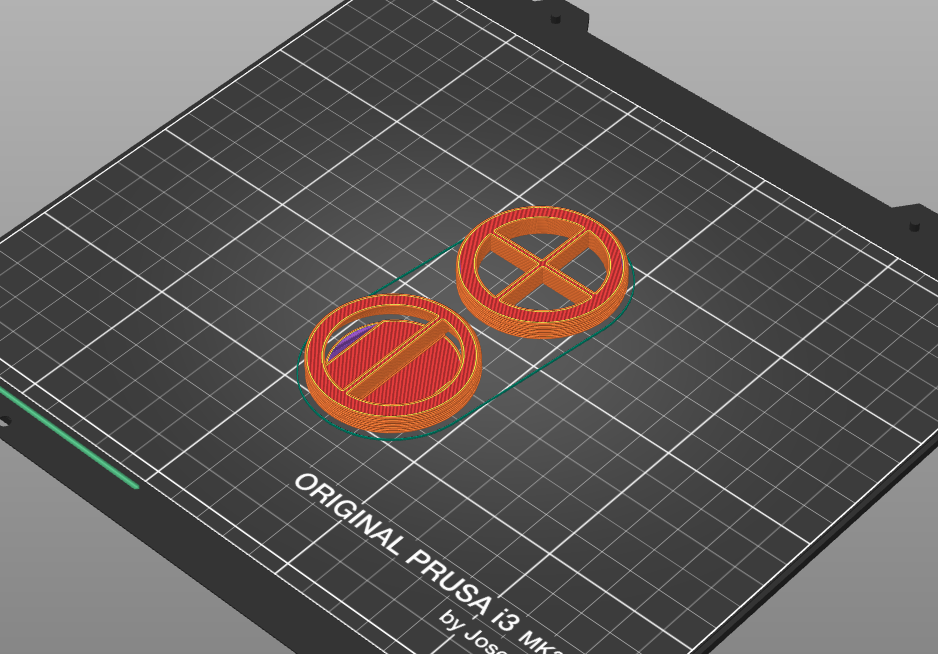

When chosoing the thicknes of the membrane (_either the rigid membrane as on the picture on the left, or the flexible membrane for the picture on the right_), you can think about the layer height you will be using, and try to slice the membrane with different parameters before printing.

## 4 - Parameters

If you want to changes the parameters of this design, you can edit the _Freecad_ file [3Dfiles/one_way_valve.FCStd](./3Dfiles/), which is fully parametric, with parameters present in the **Spreadsheet**.

If you want/need to change parameters, we would suggest you play with them and try to understand the impact of each parameters. We will only explain a small selection of important parameters that you are most likely to have to edit.

We will only describe a few parameters that you are most likely to have to change.

### 4.a - Structural parameters

_**wall_thickness** :_ \[_default=2.7mm_\] The wall thickness accross the print (_except for the strap attachment point_). Can be tweeked to make the print either stronger or weaker but lighter and faster to print.

_**snap_fit_clearance** :_ \[_default=0.09mm_\] The clearance between two objects that would fit togeteher with difficulty. Also impact the clearance betwen threads.

### 4.b - Geometrical parameters

_**owv_membrane_diameter** :_ \[_default=40mm_\] Diameter of the membrane, he bigger the membrane the more airflow there will be and the lower the cracking pressure will be, wih the obvious drawback of having a larger valve.

_**owv_membrane_center_thickness** and **owv_separate_membrane_center_thickness** :_ \[_default=0.53mm and 1mm_\] Thickness at the center of the membrane (_respectively for the membrane insert and for the separate membrane_), the thicker the membrane the higher the cracking pressure, but also the quicker the valve will close when airflow is stopped. The center thickness of the membrane has more impact on the bending force requiered to bend _the whole_ membrane.

_**owv_membrane_side_thickness** and **owv_separate_membrane_side_thickness** _ :_ \[_default=0.3mm and 5mm_\] Thickness at the side of the membrane (_respectively for the membrane insert and for the separate membrane_). The side thickness of the membrane has more impact on the bending force requiered to bend _only the tip_ of the membrane, where most of the airflow actually passes.

There is not much to be know abount printing this one-way valve : You can use prety much any material, although PETG is prefered for he membrane as it is flexible and won't fatigue over time.

When chosoing the thicknes of the membrane (_either the rigid membrane as on the picture on the left, or the flexible membrane for the picture on the right_), you can think about the layer height you will be using, and try to slice the membrane with different parameters before printing.

## 4 - Parameters

If you want to changes the parameters of this design, you can edit the _Freecad_ file [3Dfiles/one_way_valve.FCStd](./3Dfiles/), which is fully parametric, with parameters present in the **Spreadsheet**.

If you want/need to change parameters, we would suggest you play with them and try to understand the impact of each parameters. We will only explain a small selection of important parameters that you are most likely to have to edit.

We will only describe a few parameters that you are most likely to have to change.

### 4.a - Structural parameters

_**wall_thickness** :_ \[_default=2.7mm_\] The wall thickness accross the print (_except for the strap attachment point_). Can be tweeked to make the print either stronger or weaker but lighter and faster to print.

_**snap_fit_clearance** :_ \[_default=0.09mm_\] The clearance between two objects that would fit togeteher with difficulty. Also impact the clearance betwen threads.

### 4.b - Geometrical parameters

_**owv_membrane_diameter** :_ \[_default=40mm_\] Diameter of the membrane, he bigger the membrane the more airflow there will be and the lower the cracking pressure will be, wih the obvious drawback of having a larger valve.

_**owv_membrane_center_thickness** and **owv_separate_membrane_center_thickness** :_ \[_default=0.53mm and 1mm_\] Thickness at the center of the membrane (_respectively for the membrane insert and for the separate membrane_), the thicker the membrane the higher the cracking pressure, but also the quicker the valve will close when airflow is stopped. The center thickness of the membrane has more impact on the bending force requiered to bend _the whole_ membrane.

_**owv_membrane_side_thickness** and **owv_separate_membrane_side_thickness** _ :_ \[_default=0.3mm and 5mm_\] Thickness at the side of the membrane (_respectively for the membrane insert and for the separate membrane_). The side thickness of the membrane has more impact on the bending force requiered to bend _only the tip_ of the membrane, where most of the airflow actually passes. The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

The valve insert shown above (_located at_ [3Dfiles/owv_membrane_insert.stl](./3Dfiles/)) is a thin membrane made out of "_normal_" 3D printing material, with the membrane being one part with the threaded insert that screw into the body of the valve.

Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

Here we see the second alternative which is a slightly thicker membrane (_located at_ [3Dfiles/owv_separate_membrane.stl](./3Dfiles/)) made out off flexible filament (_here shown in blue_), with a separate rigid insert (_located at_ [3Dfiles/owv_separate_membrane_insert.stl](./3Dfiles/)) that hold this membrane.

There is no large advantage from using a flexible filament, appart from a potentially lower cracking pressure obtainable from a smaller valve diameter.

## 1.b - Stopper

We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

We also provide a stopper insert (_located at_ [3Dfiles/owv_stopper.stl](./3Dfiles/)) which can be used to temporarily fully close the one-way valve.

## 2 - Assembly

Once you have printed all the requiered pieces as described in the [_3D printing section_](#3-3d-printing), the assembly is simply done in three steps :

We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

We first screw the base (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)) into the valve body, with the smoothest part of the insert (_typically the part that was printed down_) pointing toward the exit of the valve (_where this face will interface with the membrane_).

We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

We then screw the membrane (_either one of the options shown in the [membrane section](#1-a-membrane-design)_) so that it seals with the cap we just screwed in.

Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing

Finaly, if we want to have a filter we can now put it into the body and hold it by screwing in anther cap (_located at_ [3Dfiles/owv_base_cap.stl](./3Dfiles/)). This can also be done at the other hand of the valve, where then the cap and the base (_which are the same model_) will be stuck together with the flter material inbetween.

## 3 - 3D printing

There is not much to be know abount printing this one-way valve : You can use prety much any material, although PETG is prefered for he membrane as it is flexible and won't fatigue over time.

When chosoing the thicknes of the membrane (_either the rigid membrane as on the picture on the left, or the flexible membrane for the picture on the right_), you can think about the layer height you will be using, and try to slice the membrane with different parameters before printing.

## 4 - Parameters

If you want to changes the parameters of this design, you can edit the _Freecad_ file [3Dfiles/one_way_valve.FCStd](./3Dfiles/), which is fully parametric, with parameters present in the **Spreadsheet**.

If you want/need to change parameters, we would suggest you play with them and try to understand the impact of each parameters. We will only explain a small selection of important parameters that you are most likely to have to edit.

We will only describe a few parameters that you are most likely to have to change.

### 4.a - Structural parameters

_**wall_thickness** :_ \[_default=2.7mm_\] The wall thickness accross the print (_except for the strap attachment point_). Can be tweeked to make the print either stronger or weaker but lighter and faster to print.

_**snap_fit_clearance** :_ \[_default=0.09mm_\] The clearance between two objects that would fit togeteher with difficulty. Also impact the clearance betwen threads.

### 4.b - Geometrical parameters

_**owv_membrane_diameter** :_ \[_default=40mm_\] Diameter of the membrane, he bigger the membrane the more airflow there will be and the lower the cracking pressure will be, wih the obvious drawback of having a larger valve.

_**owv_membrane_center_thickness** and **owv_separate_membrane_center_thickness** :_ \[_default=0.53mm and 1mm_\] Thickness at the center of the membrane (_respectively for the membrane insert and for the separate membrane_), the thicker the membrane the higher the cracking pressure, but also the quicker the valve will close when airflow is stopped. The center thickness of the membrane has more impact on the bending force requiered to bend _the whole_ membrane.

_**owv_membrane_side_thickness** and **owv_separate_membrane_side_thickness** _ :_ \[_default=0.3mm and 5mm_\] Thickness at the side of the membrane (_respectively for the membrane insert and for the separate membrane_). The side thickness of the membrane has more impact on the bending force requiered to bend _only the tip_ of the membrane, where most of the airflow actually passes.

There is not much to be know abount printing this one-way valve : You can use prety much any material, although PETG is prefered for he membrane as it is flexible and won't fatigue over time.

When chosoing the thicknes of the membrane (_either the rigid membrane as on the picture on the left, or the flexible membrane for the picture on the right_), you can think about the layer height you will be using, and try to slice the membrane with different parameters before printing.

## 4 - Parameters

If you want to changes the parameters of this design, you can edit the _Freecad_ file [3Dfiles/one_way_valve.FCStd](./3Dfiles/), which is fully parametric, with parameters present in the **Spreadsheet**.

If you want/need to change parameters, we would suggest you play with them and try to understand the impact of each parameters. We will only explain a small selection of important parameters that you are most likely to have to edit.

We will only describe a few parameters that you are most likely to have to change.

### 4.a - Structural parameters

_**wall_thickness** :_ \[_default=2.7mm_\] The wall thickness accross the print (_except for the strap attachment point_). Can be tweeked to make the print either stronger or weaker but lighter and faster to print.

_**snap_fit_clearance** :_ \[_default=0.09mm_\] The clearance between two objects that would fit togeteher with difficulty. Also impact the clearance betwen threads.

### 4.b - Geometrical parameters

_**owv_membrane_diameter** :_ \[_default=40mm_\] Diameter of the membrane, he bigger the membrane the more airflow there will be and the lower the cracking pressure will be, wih the obvious drawback of having a larger valve.

_**owv_membrane_center_thickness** and **owv_separate_membrane_center_thickness** :_ \[_default=0.53mm and 1mm_\] Thickness at the center of the membrane (_respectively for the membrane insert and for the separate membrane_), the thicker the membrane the higher the cracking pressure, but also the quicker the valve will close when airflow is stopped. The center thickness of the membrane has more impact on the bending force requiered to bend _the whole_ membrane.

_**owv_membrane_side_thickness** and **owv_separate_membrane_side_thickness** _ :_ \[_default=0.3mm and 5mm_\] Thickness at the side of the membrane (_respectively for the membrane insert and for the separate membrane_). The side thickness of the membrane has more impact on the bending force requiered to bend _only the tip_ of the membrane, where most of the airflow actually passes.